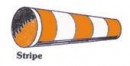

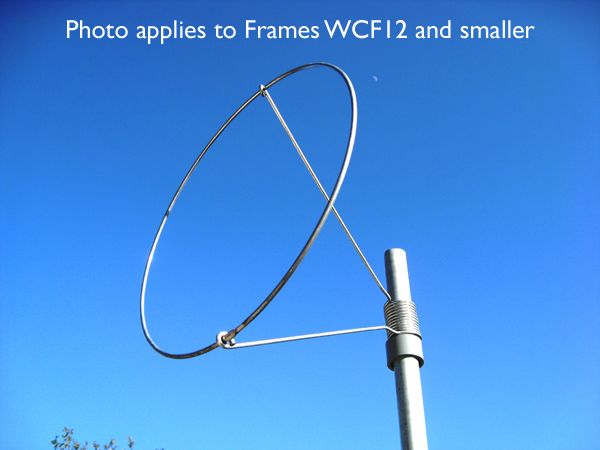

Airport Orange And White Windsocks

Overview

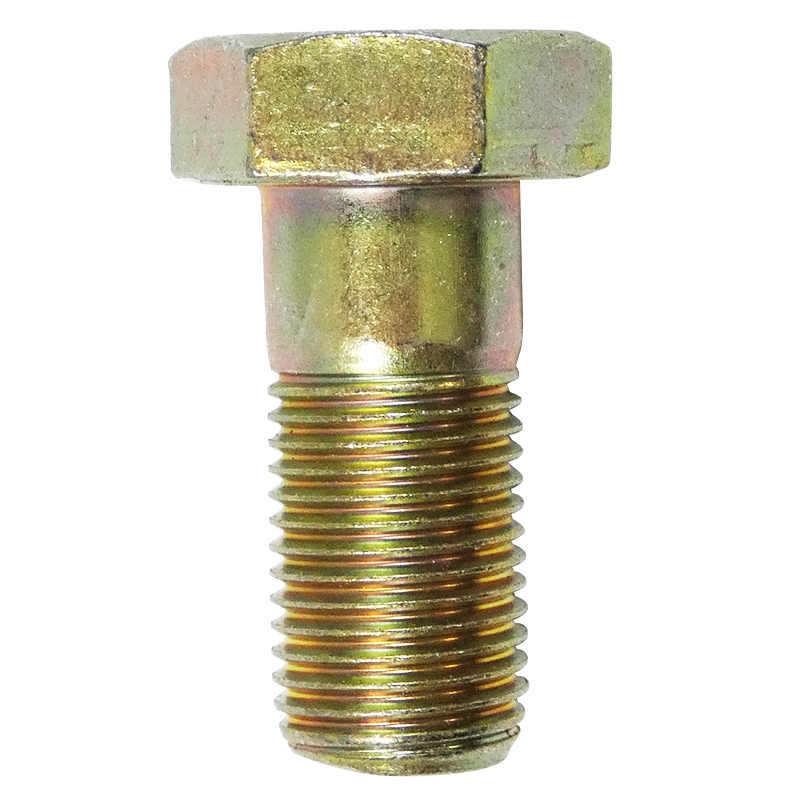

| What makes our aviation windsocks different? Two major things make a windsock, its material and its construction. We start off with a premium nylon fabric that is made right here in the USA to our exacting standards. Nylon offers unparalleled windsock durability to the elements and will not become rigid in cold weather, keeping our windsocks extremely responsive in even the slightest of wind. From there it gets urethane coated and UV protected, giving the windsock superior fade resistance and color retention. The material is subjected to a variety of tests by an independent lab to verify its structural integrity and UV resistance. This superior material is then cut and sewn right here in our own facility. Our reinforced double stitched hems and heavy duty brass grommets, assures our windsocks long life reliability. Why do we go through the added expense of a superior material and manufacturing process? To meet our customers needs. These are just a few of our demanding windsock customers. US Military US Coast Guard US Embassies State Airports Offshore Oil Rigs Nuclear Power Plants Medical Heliports Government Bio Hazard Units |