Engine Or Propeller Balance Master

Overview

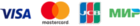

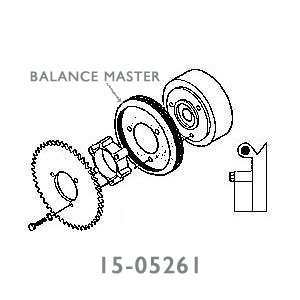

| Balance Masters® are Patented, Designed, Manufactured and Distributed in the U.S.A. and are easy-to-install devices for propellers and Rotax engines. These devices cut the vibration factor on ultralight aircrafts by as much as 50 percent when both balancers are installed. Balance Masters® are weighted with a high density liquid mass (Quick Silver). The physical principles of centrifugal and gyroscopic forces explain the action of the Balance Masters®. With the Balance Masters installed, the weighted liquid mass (Quick Silver) in the apparatus shifts during spinning, and adjusts to compensate for imbalances due to such factors as changes in flying conditions or warpage in the propeller, from nicks and rocks during takeoffs and landings. The Propeller Balance Masters® mounts on the propeller shaft or gear box in conjunction with the propeller. It is less than 7 inches in diameter. The Engine Balance Master is made to fit most Rotax engines and bolts under the Starter Pulley on the Fly Wheel side of the engine. It is less than 5 inches in diameter. Each device weighs about 4 oz. Installation will take about 25-30 minutes using ordinary hand tools for each device. Balance Master is designed to fit most propeller bolt patterns and Rotax engines from 277FA through 582. We will need to know the manufacturer of your propeller and engine model to determine the right configuration. On engines with reduction gear box can be used a second balancer on the crankshaft, installed as shown in the diagram. The installation of the two balancers, the propeller and crankshaft, gives the highest level of vibration reduction. 15-05828: Off-Set Prop Balancer 15-09450: Balancer for engine Rotax 912, 914 15-05261: Balancer for engine Rotax 377, 447, 503 15-05260: Balancer for engine Rotax 582, 618 |