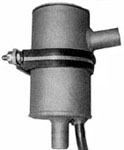

Crankcase Vacuum Kit Complete

Артикул: 05-12429

33546 27955 руб.

Наличие: – Есть в наличии у нашего поставщика. Доставка на наш склад в течение 5...6 недель после оплаты Вами заказа.

Overview

| Anti-Splat-Aero is very proud to offer this complete, very reliable crankcase vacuum valve kit. Included are the 321 stainless steel saddle mount fitting, mounting clamps, vacuum valve assembly and a complete safety by-pass with a .25 psi internal pop-off valve. This will put the finishing touch on your oil separator installation or breather system. We have had many requests for these items to enhance the installation and realize that it may be very difficult for many people to obtain these items locally or to accomplish the task of welding it into the exhaust. Now all that is required to install this performance system is to drill a 5/8? clearance hole and clamp it on. Full installation and maintenance instructions will be included. This one way vacuum check valve accomplishes a number of things, (all being good) and greatly enhances performance of your aircraft. I will attempt to touch on some of the benefits here. This assembly, when fitted to your engine will create a vacuum in the crankcase of 5 or 6 inches when in operation. It accomplishes this via two separate actions, #1 exhaust flow over the bias cut tube, and # 2 the pumping action of the engine crankcase volume changing with rotation. The one way valve allows the crankcase to exhale only, and this action creates a low pressure in the crankcase. The engine is sealed and the only air path in is through the piston ring end gap or the valve guides. This usually cuts oil consumption in half, or stops it all together, as the stated areas are where the losses occur. Your engine will virtually stop all leaks and seeping when in service, due to the vacuum inside. This system stops any possibility of freezing up the breather tube in cold climates, as no moisture laden air is present in the engine and none can be inhaled through the overboard draft tube. The rarefied air and low pressure in the crankcase has a very dramatic effect on windage and oil in suspension, thus freeing up a little power and adding some efficiency. This will also greatly lower the boiling point of any moisture that finds it?s way into the engine. Any oil temperature over 160 degrees will get rid of all the moisture in turn the acids. Any lowering of pressure on the underside of the pistons is exactly the same as adding cylinder pressure on top. This results in a very noticeable power increase (on the average 180 HP engine, 3 to 5 HP). We hear this over and over with reports of higher static RPM, better climb and acceleration, lower fuel burn etc. The belly of your airplane will stay immaculately clean as anything that exits the separator or breather line will be consumed in the exhaust stream. |