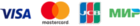

Tanis Sleeving / Varglas Non-fray Ho #3 Red

Overview

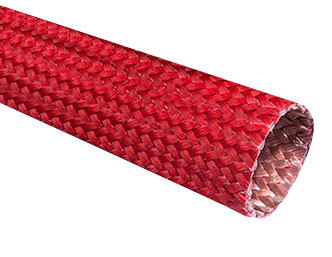

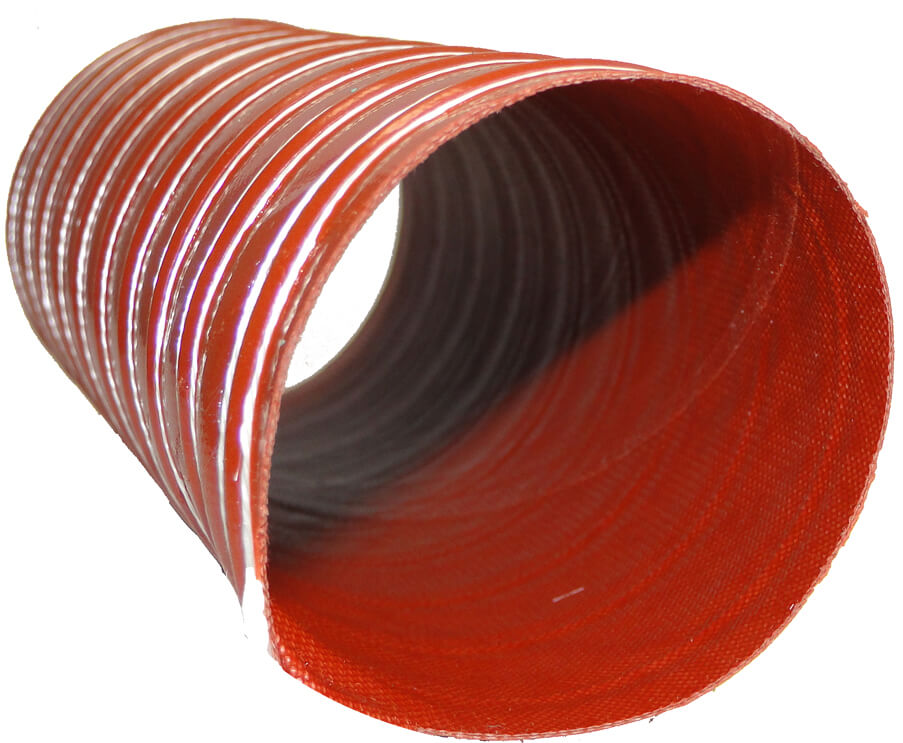

| Varglas Non-Fray Sleeving is flexible, high-temperature secondary insulation made from closely braided, continuous filament fiberglass which has been heat-cleaned to remove impurities in the yarn and to retard fraying. Type HO: Heat cleaned and treated with an acrylic resin binder (natural or pigmented). Binders are applied to further retard fraying and to hold sleeving round for cutting. HO may be less vivid after exposure to 150°C. Will serve as secondary insulation unaffected indefinitely through a temperature range from -60°C to 316°C and withstand up to 616°C for shorter periods. Since there is no impregnant that will provide dielectric protection at those extremes, these sleevings require heavy or multiple-wall thicknesses if used as primary insulation. |