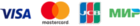

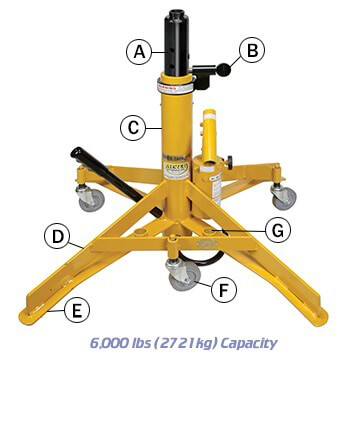

| This Series has an ultra-low design that provides maximum single stage stroke while maintaining excellent stability throughout the lifting range. These Aircraft Jacks are ideal for low-slung airplanes and helicopters weighing up to 8000 lbs. (3629kg). A: INNER SLIDE TUBE - The 2.5" (64mm) diameter powder-coated Tube forms the foundation of the TriTask Aircraft Jack System. The zigzag pattern of safety lock-out holes are vertically spaced 1" (25mm). A 1.25" (32mm) round Jacking Point receiving socket is at the top of the Tube's anchoring stud.

B: POSITIVE SAFETY LOCK - Spring-loaded safety pin "pops" into the Inner Slide Tube and rests on top of the Jack's frame to prevent the accidental lowering of the aircraft.

C: ANTI-SNAG ROUND FRAME TUBE has a 3.25" (83mm) diameter.

D: LOW-HEIGHT LEG DESIGN provides maximum gear door clearance, with one of the four sections completely free of any protrusions. The four legs insure excellent stability with its 27.062 (68.7cm) square footprint.

E: MILLED FLAT AREA ON EACH LEG increases surface contact to help prevent any hanger floor damage.

F: THREE 3" (76mm) SPRING LOADED CASTERS allow easy transporting of the Jack around the hanger without the need for the steel legs to scuff across the floor.

G: TWO ACCESSORY TUBES are provided to allow the operator to put in accessories or tools for on-board storage if desired.

H: The optional ALW-10 Leveling Washer Set is a perfect solution when it's necessary to shim the A500 or A600 Aircraft Jack legs because the hanger floor isn't completely flat or level. The ALW-10 Set isn't to be used with the A300 or A700 Series Jacks. |