Aeropoxy Laminating Epoxy

от 6557 5464 руб.

до 602594 502161 руб.

Наличие: Проверяйте наличие по каждому товару

При добавлении в корзину к цене товара добавится таможенное оформление опасного груза. Окончательную стоимость Вы увидите при оформлении заказа.

Overview

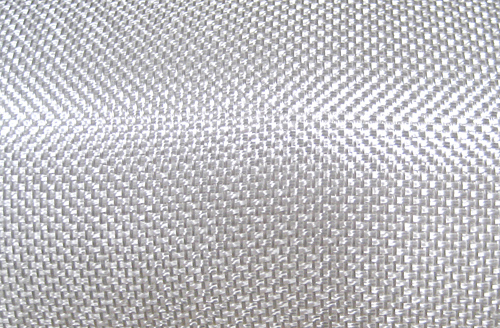

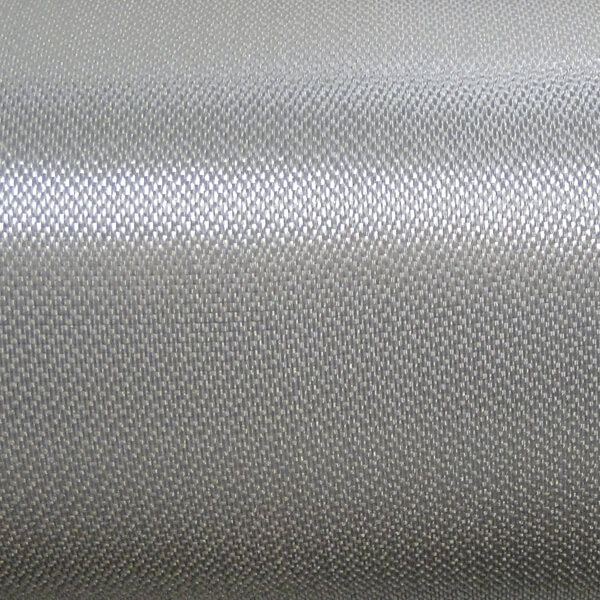

| PR2032 is a medium viscosity, unfilled, light amber laminating resin that is designed for structural production applications. Three hardeners are available for use with PR2032. PH3660, has a 1-hour pot life. When used with either of these hardeners, the system gives excellent wet-out of fiberglass, carbon and aramid fibers. Special additives have been incorporated into this system to promote chemical adhesion to fabrics made with these fibers. The AEROPOXY systems will cure completely at room temperature, or can be given an elevated temperature cure. AEROPOXY contains no MDA (a known liver toxin and carcinogen) and meets or exceeds current OSHA requirements for safe use. It satisfies all structural, pot life and wet-out characteristics according to tests by Rutan Aircraft Factory, and RAF recommended its use for all homebuilt aircraft applications. The best ratio on AEROPOXY is 100:27 by weight or 3 to 1 by volume. In early 1996 several improvements were made to AEROPOXY. The viscosity was lowered for easier laminating, the occasional slight surface tackiness in high humidity was eliminated, the AEROPOXY hardeners were modified to prevent any tendency to crystallize in high humidity, and the mix ratios were modified to an exact 3 to 1 by volume. |