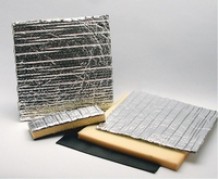

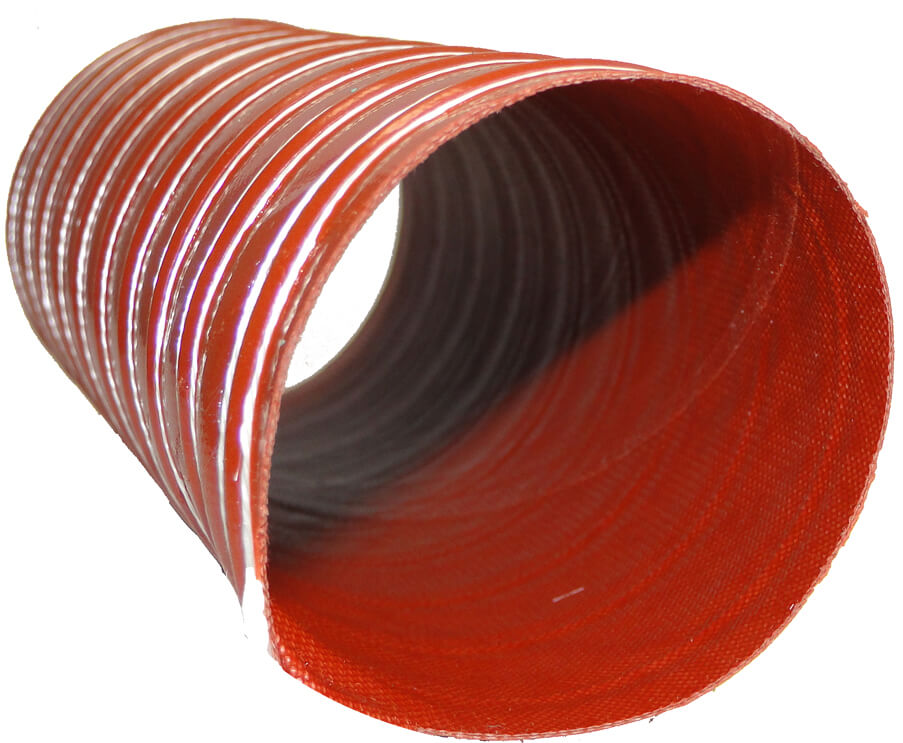

Fiberfrax

Overview

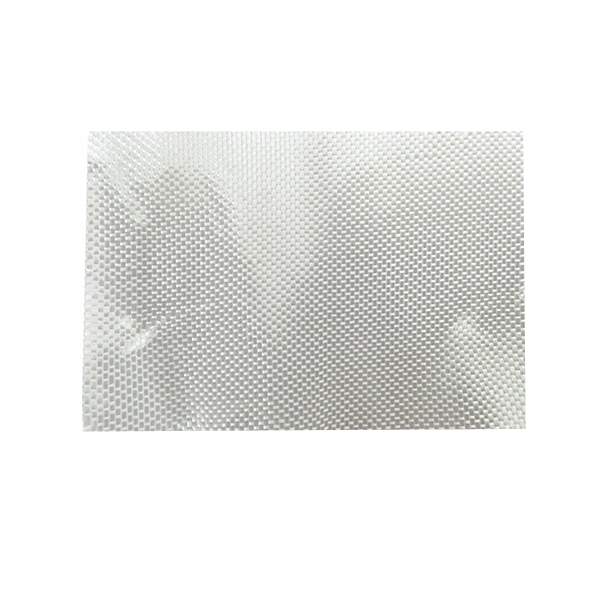

| A new material made from washed ceramic fibers with binders added to form a lightweight, flexible asbestos-free insulation. Withstands temperatures to 2300 F. Excellent for aircraft firewalls. Available in 24" wide. Sold by the foot. |