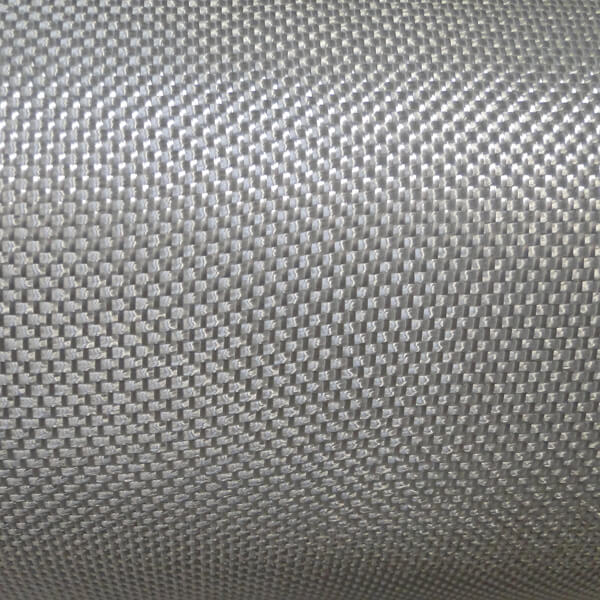

Rutan Fiberglass Cloths

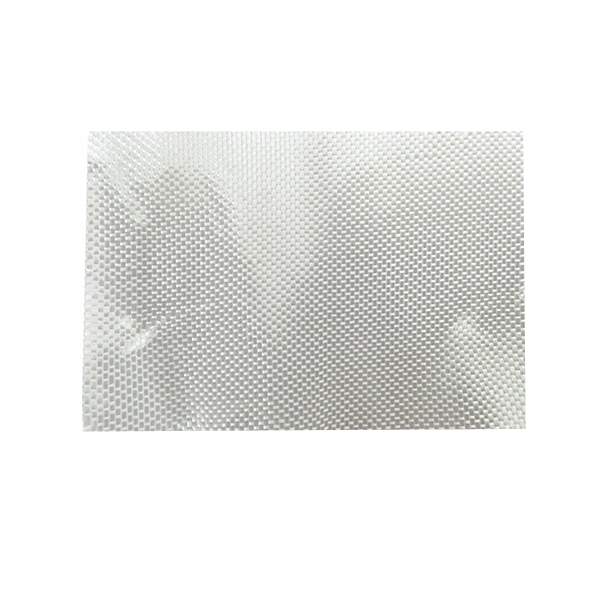

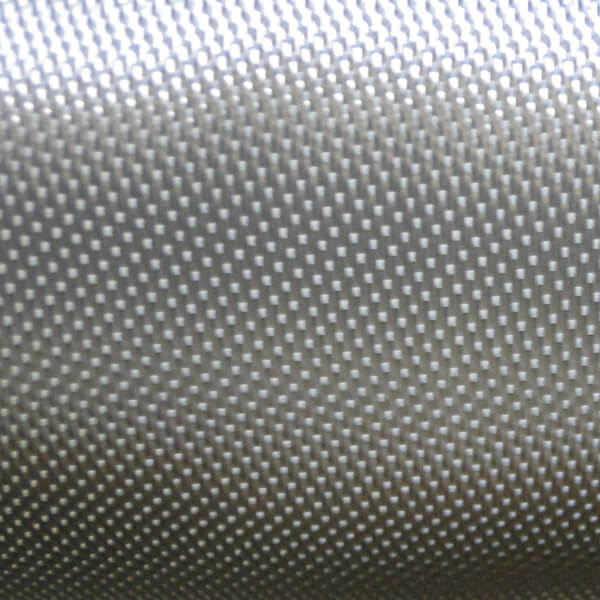

Overview

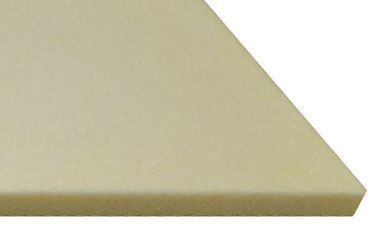

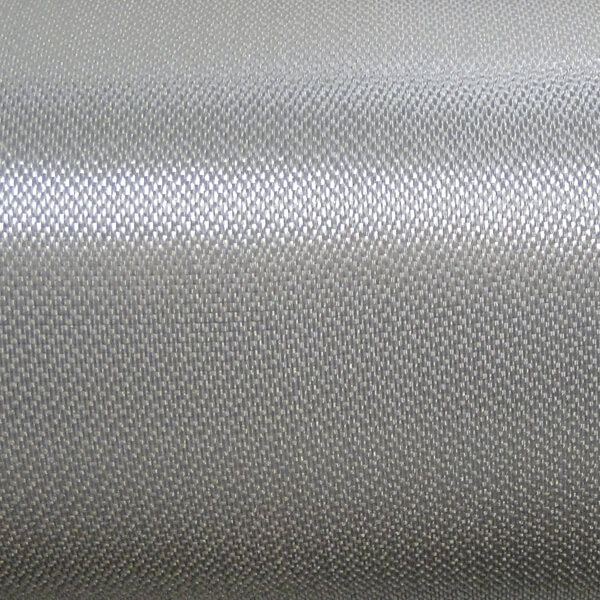

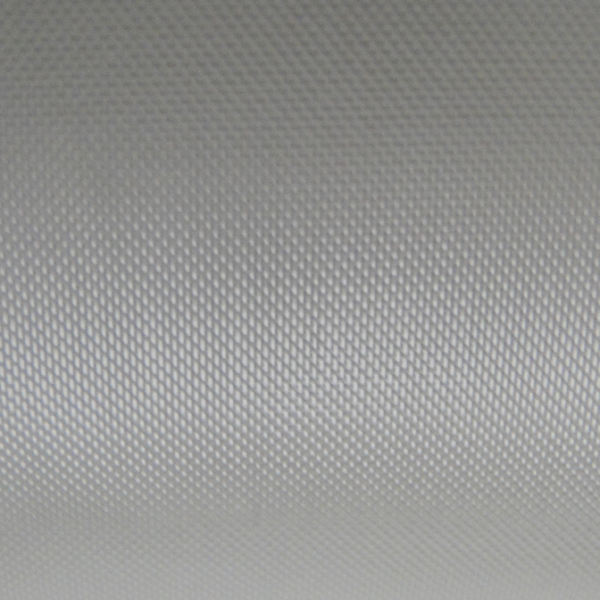

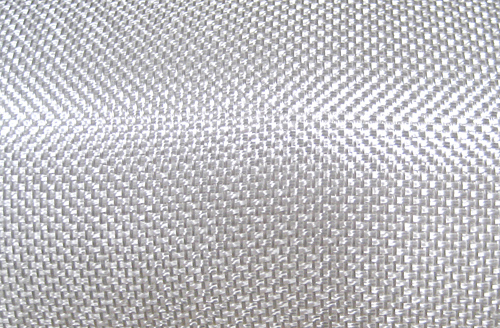

| Note: 38" wide. Sold by the yard The most basic structural material in building a composite aircraft is glass cloth. The use of glass in aircraft structures, particularly structural sandwich composites, is a recent development. Glass cloth is available commercially in hundreds of different weights, weaves, strengths and working properties. Very few of these, however, are compatible with aircraft requirements for high strength and light weight. Even fewer are suitable for the hand-layup techniques developed by Burt Rutan for the homebuilder. The glass cloth featured here has been specifically selected for the optimum combination of workability, strength and weight. Two types of glass cloth, a bi-directional cloth and a uni-directional cloth are used. BID cloth has half of the fibers woven parallel to the selvage edge of the cloth and the other half at right angles to the selvage, giving the cloth the same strength in both directions. UND cloth has 95% of the glass fibers woven parallel to the selvage, giving exceptional strength in that direction and very little at right angles to it. BID is generally used for pieces which are cut at a 45° angle to the selvage, a bias cut, which enables the builder to lay BID into contours with very little effort and provides the needed shear and torsion stiffness for flying surfaces. UND is used in areas where the primary loads are in one direction, such as wing skins and spar caps. Multiple layers of glass cloth are laminated together to form the aircraft structure. Each layer of cloth is called a "ply". |