| LOW OIL SENSOR

This sensor is unique! It can be installed in the bottom of the engine?s oil pan. It can even be used as the oil drain plug on most engines. This sensor was originally designed for small Lycoming engines, but can be utilized on several other engine types as well.

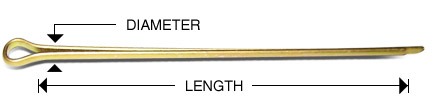

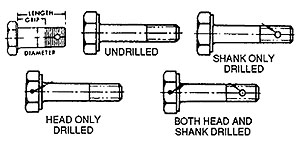

The sensor utilizes a 1/2" NPT fitting so that it can be inserted directly into the oil pan of most small Lycoming Engines. The 5/8" x 5/8" square bolt head of this sensor has been drilled (0.08" dia.) to accept a safety wire. WHY PURCHASE a LOW OIL LEVEL SENSOR?

This question is easy to answer. If you rely on a low oil pressure indication to tell you that your engine has run out of oil, it?s TOO LATE! You?ll most likely have to glide to safety, power off, . . and land in an area that is difficult get down safely.

Many pilots have lost oil while flying. Just review the aircraft accident statistics. The reasons have been, loose bolts on the engine?s cylinder covers, loose hose connections, broken or chaffed oil lines, or just loose hardware in general concerning the oil system.

Even a relatively slow oil leak can down an aircraft. Consider this; . .Most aircraft can fly 3 to 4 hours on a cross country without refueling or you getting out to check the oil. If you had 8 quarts in your engine at take-off, you only have to lose less than 1 oz. / minute to be empty at the end of your cross country!! SENSOR DESIGN

Our sensor is designed so that the contacts are normally open when the the engine oil is full or OK. The reason for this is simple. We want to extend the life of your sensor. If the sensor contacts were designed the opposite way, the engine vibration would constantly be rubbing the contacts together. This would make the sensor life shorter. WARNING LIGHT

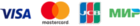

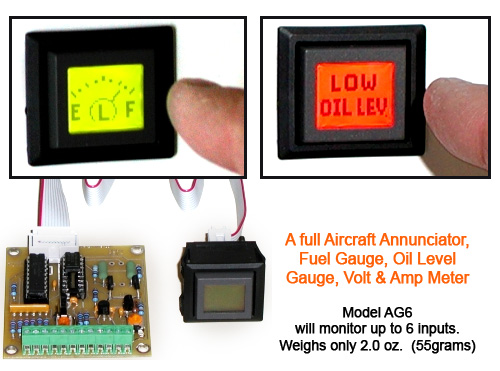

You can utilize our "flashing panel light", a relay, or utilize your own panel indicator. The maximum current draw for any light or relay is 0.2Adc. Our light is included in the electronics package. The light can be mounted in the instrument panel using a 0.249" to 0.254" diameter mounting hole. The light supplied will operate from a +12Vdc system. To make this system +24V compatible, you will need to add a 12V zener diode in series with our flashing panel light.

The zener should be a 14V, 1W, 1N5244 or equivalent. You MUST connect the band of this zener to your +24V. The other end will be connected to the flashing panel light, (RED) wire. The (BLACK) wire of the flashing panel light will be connected to one wire of the sensor. The remaining sensor wire will be wired to common (Chassis Ground). This zener will be supplied by us for the asking for +24V systems.WHEN WILL THE SENSOR INDICATE A LOW LEVEL?

This sensor package indicates a low oil level that is less than 4 quarts in a Lycoming O-360-A1A. The actual oil capacity will vary with engine and oil pan type. Since the Lycoming manual for this engine says that it will run on just 2 quarts of oil, you should have plenty of time to find an adequate landing spot to add oil! The sensor will indicate an alarm when the oil level is less than 3" from the bottom of the oil pan plug hole. To find out where your low oil level will be, you will have to add oil to the engine slowly and see where the alarm goes away. Make sure you check your engine?s lowest operating oil level against the actual oil level that is indicated by this sensor before relying on this sensor for your low level warning. Compatibility: The drawing IS provided for you to determine compatibility on other engines.

PLEASE READ THIS before ORDERING!

We would like to guarantee that this sensor will work for you before you order it. In order to do this, you will need to ensure that you have 3.75" or so of vertical clearance up into your oil pan to utilize this sensor. This distance is measured from the very bottom of the 1/2" NPT plug hole. It is also the measurement from the top of our sensor to the half way point on the threads of the sensor. The position of the bottom of this hole may not be located at the bottom of your oil pan. Most plugs extend a little lower than the bottom of the oil pan. You should remove your oil pan plugs, insert a ruler, and measure the distance it takes to insert this ruler before you feel an obstruction. If this distance is 3.75" of greater, the sensor will work (if you do not screw it in beyond the half way point on the threads).

For example, the Lycoming O-360-A1A oil pan can have 1, 2, or 3 ports on the bottom of the oil pan. Some are closed off, others are just plugged. On this engine, you will have to use one of the ports on the Pilot?s side of the oil pan to utilize this sensor. The passenger?s side of this oil pan cannot accept this sensor because there is an air intake pipe that enters the oil pan on that side. The bottom of this pipe measures approximately 2.75" above the bottom of the plug opening. This distance is less than the required 3.75" needed to utilize this plug. |