With Heat Pack option adds a shipping heat pack to keep the material from freezing while in transit. It is recommended for winter months / destinations in cold climates where the temperature may drop below freezing while in transit. If the material freezes, it is not recommended for use.

Stewart Systems Primer Sealer is a high quality, water-based single component primer, not requiring any catalyzing agent. Performance obtained is equal or superior to that of two-component, catalyzed epoxy systems. Primer Sealer offers good coverage, excellent durability, and ease of application, as well as being a low VOC and EPA compliant coating.

ENVIRONMENTAL ADVANTAGE

It is a low VOC (Volatile Organic Compound). high performance production coating. It is considered non-hazardous by EPA definitions and does not contain lead or chromates. The solid and semi-solid sludge produced in spraying and clean up can be flocculated; dried and sent to a "Class B" landfill. Check with your local and state regulations for proper handling. CHARACTERISTICS - Excellent exterior durability

- Excellent hardness/impact resistance

- Excellent mar and abrasion resistance

- Excellent adhesion on plastics, gelcoat and composite substrates

- Solvent resistant

- Can be applied in a wide variety of temperature and humidity conditions without the use of retarders

- Distilled water is used for reduction

- Water is used for clean-up

- Non-Hazardous

- Air dry or force curing preferred

- Can be oven baked

- Wide range of colors to promote topcoat coverage

- Coating will not flash rust on bare metal

- Shelf life of 1+ years

- Unused paint can be returned to container

- Non-Flammable

USES - Steel, Aluminum, Fiberglass, Wood, Plastics, Concrete, PVC, Pre-Finished Siding, Steel Decks

AIR QUALITY DATA - VOC (Volatile Organic Compounds) 2.0 lb/gal; 240 gm/ltr

- Free of lead and chromates

PHYSICAL DATA - Liquid Boiling Point: 336°F

- Specific Gravity: >1

- % Solid by weight: 43.2%

- Vapor Density: Heavier than air

- % Solid by volume: 40.62%

- Evaporation Rate: Slower than ether

- Weight per gallon: 10.36 lbs.

- pH: 7-8.5

- Flash Point: 150°F CC

- VOC: 2.0 lb/gal; 240 gm/ltr

PERFORMANCE DATA - Theoretical Coverage at I mil: 660 ft2 (1624 x 40.62% solids by volume)

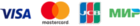

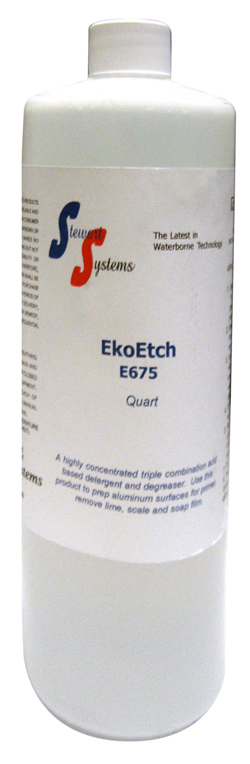

SPECIFICATIONS - METALS: Surface must be free of grease, oil, dirt, and other foreign matter. Oxidation material must be removed or converted with Aircraft Finishing Systems Conversion Coating.

- FIBERGLASS: Surface must be free of grease, oil, dirt, and other foreign matter.

- CONCRETE: Surface must be free of grease, oil, dirt, and other foreign matter.

MIXING DIRECTIONS 1. Application area temperature should be between 70 and 85 degrees Fahrenheit.

2. Mix well before using. DO NOT SHAKE...STIR ONLY Make sure any solids that might have settled to the bottom are mixed back into suspension.

3. Thin by adding 10% distilled water (by weight). SS EkoPrime Primer/Sealer may be sprayed right out of the bottle for heavy build up to fill scratches.

4. Always pour mixed and thinned primer through a medium paint filter before spraying. SPRAY APPLICATION 1. The first coat of SS Waterborne Primer/Sealer is applied as a light tack coat. Allow to dry untill tacky.

2. Apply 2nd coat to achieve solid coverage.

3. If top coating is desired, allow to dry. Lightly sand with 320 grit open coat sandpaper or ScotchBrite with red ScotchBrite pad. BRUSHING & ROLLING For best results we advise spraying. But, if brushing or rolling is desired, you can achieve a nice finish with a foam brush or roller. Do not thin the primer with additional water unless it will not flow out. CLEAN UP Clean equipment immediately with water. |